Hydraulic Cylinders is Industrial hydraulic cylinder

Most of us are all too familiar and seem to know a lot about hydraulic cylinders (known in the south as Hydraulic bending).

However, there are also a lot of people who are confused when encountering self-design, choosing a hydraulic cylinder that suits their needs.

This article will focus on the introduction, classification, hydraulic cylinder in the powertrain.

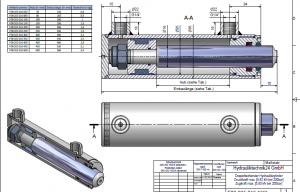

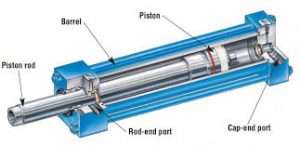

The first is the concept, the names of the parts of the hydraulic cylinder. The figure below shows the name of some parts of a hydraulic cylinder.

Hydraulic cylinder structure

– Barrel: Cylinder cover

– Pistons: Pistons

– Cylinder rod: Rolling cylinder

– Gland: Stock cylinder

– Eye / Clevis battery: Plugged ear

– Ports: Line of oil feeding in / out cylinder

– Piston seal; Rod seal, Wear ring; O-ring; Wiper …: Sealing gasket

Working parameters and dimensions of hydraulic cylinders:

The 3 most important parameters of a hydraulic cylinder are:

Bore diameter: Denoted by D

Rolling diameter (rod): Symbol is d

Stroke, stroke, stroke of cylinder, – s.

D and d denote the size and ability to generate thrust / pull on the cylinder

S denotes the length and reach, working range of the cylinder.

Classification hydraulic cylinder

Hydraulic cylinders are usually divided into two basic groups:

Sigle-acting (one-way) cylinder

or Double acting cylinder (Two-way cylinder).

One-way cylinder

One-way cylinders only produce one-sided thrust, usually the side that needs the cylinder,

thanks to the supply of hydraulic oil with pressure on the cylinder end.

Rolling cylinders will self-reposition thanks to the force of the outside or spring thrust inside.

The most recognizable thing for a one-way cylinder is that it has only one oil supply port.

Drawing hydraulic cylinder

Two-way cylinder

Two-dimensional cylinders can generate force on both sides:

When the cylinder rolled out and even when it indented the cylinder cover. The inner sealing structure of a two-dimensional cylinder is also more complex than a one-way cylinder and there must be two oil lines on its body.

Another big difference is that the hydraulic system using a two-way cylinder must have a directional valve (distribution valve) when you want to control this cylinder as shown below.

Cylinders can also be divided according to the type of cylinder lamination:

Single-stage rolling cylinders or telescopic cylinders.

Single-cylinder cylinder:

Single-cylinder cylinder is a type of single-cylinder cylinder that is attached tightly, moving with the piston.

This type of cylinder can only create a movement of less than the overall length of the cylinder,

ie its working distance is limited by the length of the cylinder minus the thickness of the piston and the internal assembly of the cylinder.

Single-cylinder cylinders are widely used and have wide applications.

Most of it has a structure for rolling out the cylinder on one side of the cylinder.

Some cylinders have a structure with cylinder on either side of the piston (called Double rod end cylinders).

When one side of the cylinder is protruded, the other side will “indent” into the cylinder housing.

Multi-stage cylinder

Multi-stage cylinders or Telescopic usually have 2-3-4 or sometimes up to 6 floors.

It consists of a cylinder housing and many tubes that need to be nested together.

This structure makes the cylinder can extend the journey much longer than the base size of the cylinder when fully rolled.

This creates the ability to design details, a lot of compact machine structure.

However, multistage cylinders are much more expensive than single cylinders.

Multi-stage cylinders also have two types of structures: one-way cylinders and two-dimensional cylinders;

However, two-dimensional cylinders are very complex in structure and require special designs to prevent risks.

There is also a way of classifying hydraulic cylinders according to the structure with two types: welding cylinders and tie-cylinder assemblies (Tie Rod cylinder).

Guided cylinder gaskets:

This type of cylinder is assembled and held in place by 4 high-tensile steel gaskets that lock through the thread holding parts from the ends of the cylinder caps.

(With large-diameter cylinders, there may be up to 20 holding rods.)

This type of cylinder structure makes it easy to dismantle and service the cylinders and it is also easy to manufacture from standard parts.

Cylinders of this type are often used in industrial applications.

Welding structure cylinder

Cylinder heads of this type are soldered with umbilical cord

GU-RONG hydraulic cylinder

Welding structure cylinder

The cylinder head is welded with a cylinder to help the cylinder have a strong structure suitable for heavy working modes on mechanical or industrial construction equipment.

Calculation of hydraulic cylinder design:

Hydraulic cylinder has many types, after we choose the right type, there will be a few parameters to calculate as follows:

- Thrust and pull of hydraulic cylinder

- Working pressure of hydraulic cylinder

- Working stroke of hydraulic cylinder

- Operating speed m / s Of hydraulic cylinder

From the above parameters we can force to choose hydraulic cylinders to assemble into the system.

See more:

Fabrication process of hydraulic cylinder:

Hydraulic cylinder is an indispensable part in the chain of industrial machinery.

Therefore, the use of a well-designed hydraulic cylinder and a tight production process will make the plant line operate efficiently, minimizing the possibility of damage.

- Materials: Popular steel grades such as S45C, S50C, SCM 440 …

- Shaped processing

- Heat treatment surface: 2.5mm

- Grinding Round to tolerance H7

- Hard Chrome Plating optimal thickness 60-100 um.

- Polishing: Finishing Gloss 0.2 um

- Machining the cylinder cylinder with the standard of roundness, gloss, and the most effective is Hard Chrome Plating Hydraulic Cylinder Barrel

- Seal- high quality hydraulic seals from well-known brands such as Packer, NOK …

- Assembled on dedicated assembly machine

- Hydraulic Pressure Test.

Operating Hydraulic Cylinders:

The operation of the hydraulic cylinder in compliance with the operating procedure will help the hydraulic cylinder to operate stably:

The oil level in the oil tank always reaches the safety index

Hydraulic oil ensures standard viscosity

Must have hydraulic oil filter system, avoid the residual condition will cause cylinder damage

Always try no load before commissioning

Only operate properly Load requirements that manufacturers make

When an incident occurs, it must be stopped immediately, avoiding a situation of severe damage that cannot be repaired

Always plan to suspend the machine within 6 months for maintenance warranty.

Repairing Hydraulic Cylinders

The common damage in hydraulic cylinder operation:

Hydraulic presses during operation often encounter problems that lead to damage as follows:

Damaged hydraulic power pack:

Heavy duty industrial hydraulic cylinder

The hydraulic power pack in a hydraulic press is often damaged for a number of objective reasons:

Motor failure: Replace the Motor

Broken vales system: Cleaning or replacement.

Damaged hydraulic pump: Check repair or replacement.

Damaged Hydraulic Cylinder:

Hydraulic presses in the process of working are unavoidable incidents, the most common of which is pressure drop, or flow (soy sauce).

Common causes of damage to a Hydraulic Press are as follows:

- Dirt: The dirt in the environment or the dirt from hydraulic oil, especially sand, integrated on the hydraulic seal for a long time makes the cylinder cylinder surface scratched.

- Extremely harsh environment: some hydraulic cylinders need to work in the air for long periods of time, or in harsh environments such as the sea with high salt and moisture content in the air, causing corrosion. local or full working surface of cylinder.

- Misbehavior: Hydraulics operate improperly, resulting in overload or physical damage resulting in cylinder scratches, bends, or cracks.

Maintenance of Hydraulic Cylinders

From the causes of the above damage we need periodic maintenance for the hydraulic company as follows:

- Periodically check the hydraulic company hygiene, avoid the dust and dirt in the hydraulic seal. Carry out the replacement immediately when the Seal Seal is damaged.

- Clean oil filter periodically.

- For inactive hydraulic companies, periodic cleaning of mold on the walls of the cylinders should be periodically cleaned.

- When a failure is detected, it is necessary to deactivate the equipment and carry out maintenance immediately, avoiding the situation of use that makes the equipment worse than it can be repaired.

Repair cylinder hydraulic press

MILK HYDRAULIC HYDRAULIC SHELL

Damaged hydraulic cylinder barrel

Hydraulic cylinder cover also called Ben shell

Hydraulic cylinder cover is usually scratched, or pitting. Lightly, the thin scratches on the surface, heavy scratches are deep scratches.

Hydraulic cylinder cover is scratched, pockmarked surface.

flower cylinder hydraulic brick press machine

Seal felt during use is worn, fractured or cracked.

Water pressure machine

This is the cause of hydraulic cylinder failure.

How to fix damage Hydraulic cylinder cover

- For this type we can proceed as follows:

- For the DEEP SPRAY CERAMICS, we use the non-variable welding method

- For DEEP CYLINDERS we use fillings that do not change the structure of the material, then process on lathes and grinders to get uniform size.

- For pitting and rust holes per day it is imperative to grind all the pores and plating to restore the old diameter.

- For hydraulic cylinder shells are scratched or scratched, it is required to re-polish the ball, depending on the size, choose the method of plating recovery or raise the Piston parameter.

- Seal Issues we proceed to replace.

Hard chrome plated cylinder

Chromed plating x cylinder brick molding machine

HYDRAULIC PISTON MILK

Hydraulic pistons are often scratched, pock-marked, and bumped leading to oil leakage, condensation. These types of damage need to be treated thoroughly by treating Chromium Plating for Hydraulic Piston.

Hydraulic Piston

Chromium Plating Requirement For Hydraulic Piston:

Tie Rod Hard Chrome

For hydraulic piston. Chromium plating is required to have subtle cracks to facilitate the passage of oil molecules, limiting friction with seal seals.

Each stage has a separate processing process to bring the highest efficiency, restore and improve the productivity of machinery …

Chromium Plating. Hard Hydraulic Barrel

HYDRAULIC PISTON RECOVERY PROCESS:

- Release the old Chromium layer chemically

- Check for size, and surface defects

- Conducting welding to repair surface defects

- Sharpening Piston on a specialized grinding machine

- Hit the ball to the level 10 ball

- Chromium Plating meets standard dimensions

- Polish finishing.

ASSEMBLY TESTED hydraulic cylinder

After finishing processing the hydraulic cylinder and hydraulic piston barrel of the press.

We carry out the assembly of a hydraulic press on a specialized Hydraulic Cylinder Assembly machine.

After the assembly of the hydraulic press is completed, it is connected to the hydraulic power unit and the test of pressure and load is carried out. And packaging delivery to customers.

This method has both cost savings, and the quality of the product after repair reaches 98% compared to the new product.

Our Hydraulic Press products are regularly repaired as follows:

REPAIRING hydraulic press type C

REPAIRING hydraulic presses FORM H

REPAIR HYDRAULIC COMPRESSOR FORM 4 HEAD

REPAIR HYDRAULIC COMPRESSOR FORM 4 HEAD

REPAIRING HORIZONTAL SURFACE presses

REPAIR BRICK hydraulic presses

REPAIR hydraulic press MACHINE TOLE MACHINE

REPAIR hydraulic press pressurizer

REPAIR HYDRAULIC PRESSING press

REPAIRING PRESSURE SCRAPS

REPAIR hydraulic press PRESSURE MACHINE HOA VAN

With modern machinery system, we have the ability to process hydraulic cylinders with diverse diameters, dimensions and perfect precision to meet the needs of our customers.

Xem thêm :