HYDRAULIC CYLINDER REPAIR AND RECONDITIONING

Hydraulic Cylinders: A Cost-Effective Solution for Repair and Enhanced Performance

Introduction to Hydraulic Cylinders

Hydraulic cylinders are essential components in industrial hydraulic systems, especially in applications requiring precise linear motion and powerful thrust. However, after prolonged use, the performance and durability of cylinders may degrade. As a result, hydraulic cylinder reconditioning becomes an efficient solution that helps save costs, extend equipment lifespan, and improve work efficiency.

In the industrialization and modernization process, hydraulic cylinders replace human labor, especially in applications for lifting extremely large and heavy loads. Hydraulic cylinder systems operate independently, controlled by computers and centralized control systems.

During operation, heavy-duty industrial hydraulic cylinders may face common malfunctions (common hydraulic cylinder failures).

Replacing a hydraulic cylinder or the entire hydraulic piston rod can be expensive and time-consuming. Therefore, hydraulic cylinder repair and reconditioning at Thuy Luc Sai Gon is the optimal solution.

The cost of hydraulic cylinder repair at Thuy Luc Sai Gon is only about 15% of the price of a new cylinder, while the reconditioned quality reaches 99% compared to a new cylinder. Additionally, the product is guaranteed for 12 months and can operate in harsh environments with temperatures ranging from 400 to 800 degrees Celsius or in corrosive environments like the sea or chemicals.

I. Structure and Operating Principle of Hydraulic Cylinders

Basic Structure of Hydraulic Cylinders

A hydraulic cylinder is a mechanical component that uses the pressure of hydraulic fluid to generate thrust or pull. The main components of a hydraulic cylinder include:

- Cylinder Tube: Contains the hydraulic oil and serves as the space where the piston moves.

- Piston: The moving part inside the cylinder tube, which receives pressure from hydraulic fluid to perform linear motion.

- Cylinder Rod: Connects the piston to other parts of the mechanical system, often exposed to direct forces.

- Sealing Components (Seals, O-rings): Ensure that the system does not leak oil and maintains its operational efficiency.

- Cylinder Head: Protects internal components and withstands the pressure exerted by the piston.

Operating Principle of Hydraulic Cylinders

The operating principle of a hydraulic cylinder is based on converting energy from high-pressure hydraulic fluid into mechanical force. Hydraulic oil is pumped into chambers within the cylinder tube, acting on the piston and causing linear motion. Depending on the direction and intensity of the oil flow, the cylinder can move in various directions.

II. Common Issues and Causes of Hydraulic Cylinder Failures

Throughout their use, hydraulic cylinders may encounter problems that affect their performance and longevity. Some of the main causes of hydraulic cylinder damage include:

Wear and Tear of Piston and Cylinder Tube Surfaces

Cause: Prolonged operation, the contact between metal parts can lead to wear. Additionally, poor-quality hydraulic oil or the intrusion of contaminants into the system can be primary causes of wear.

Effect: The chrome layer on the piston surface can wear out, losing its corrosion resistance and reducing performance.

Hydraulic Oil Leaks

Cause: Worn-out or damaged seals and O-rings due to high temperatures, unstable pressure, or contamination.

Effect: Oil leaks reduce system efficiency, cause environmental pollution, and pose fire and explosion risks.

Cracks, Bending, and Deformation of Cylinder Shells

Cause: Overload, external impacts such as strong collisions, or excessive temperature differences can lead to cracks or breakages in the cylinder shell.

Effect: Deformed or cracked cylinder shells will reduce pressure resistance and affect system performance.

Damaged Sealing Components

Cause: Seals and O-rings may wear out, crack, or degrade due to high temperatures, large pressures, or harsh operating conditions.

Effect: Hydraulic oil leaks lead to reduced efficiency, increased maintenance costs, and damage to other system components.

III. Hydraulic Cylinder Reconditioning Process

Hydraulic cylinder reconditioning is a complex process that requires technicians to master specialized techniques and use modern technologies. Below are the main steps in the hydraulic cylinder reconditioning process:

Inspection and Evaluation of Cylinder Condition

Before proceeding with reconditioning, technicians will inspect all parts of the hydraulic cylinder, such as the piston, cylinder tube, seals, O-rings, and cylinder shell. The purpose of this inspection is to determine the extent of damage and the root causes of the failure.Disassembling the Cylinder Components

After evaluation, the cylinder parts will be carefully disassembled using specialized tools to avoid damaging reusable components. This process includes checking each part and cleaning it thoroughly.Chromium Alloy Coating

One of the main reconditioning methods for worn-out hydraulic cylinders is applying chromium alloy plating. The chromium coating provides surface protection, corrosion resistance, wear resistance, and enhances the durability of the piston and cylinder tube.Machining and Repair of the Cylinder Shell

If the cylinder shell is cracked or deformed, technicians will use machining technologies such as welding, CNC machining, or milling to restore the original shape and size of the shell.Replacing Seals and Other Components

After restoring the main parts, seals and O-rings are replaced. These components are carefully selected to meet the required pressure, temperature, and hydraulic fluid characteristics.Reassembly and Performance Testing

After completing all the repairs and replacements, the parts are reassembled. The cylinder is then tested for functionality, pressure, and sealing. Tests include pressure testing, leakage testing, and piston movement checks.

IV. Advanced Repair Techniques

Chromium Plating and Replacement Coatings

While chromium plating is a common method, other coating methods, such as nickel plating, stainless steel plating, or tungsten alloy plating, are now available. Each type of coating has unique characteristics, such as excellent corrosion resistance and high surface hardness, improving cylinder longevity.CNC Machining and Welding for Cylinder Shells

When the cylinder shell is cracked or deformed, CNC machining, TIG, MIG welding, or resistance welding can be used to repair it. These techniques restore material strength, ensuring the cylinder shell can withstand operational pressure.Sealing and O-Ring Repair Technologies

Seals and O-rings can be reconditioned by replacing worn-out or damaged materials. Materials such as Viton, PTFE, or specialized rubber compounds are selected to ensure perfect sealing in harsh operating environments.

V. Benefits and Applications of Hydraulic Cylinder Reconditioning

Cost Savings for Businesses

Hydraulic cylinder reconditioning can save up to 85% of the cost compared to complete replacement. This is crucial in heavy industries, where equipment is expensive and requires regular maintenance.Environmental Protection

Reusing parts instead of replacing them helps reduce industrial waste, protecting the environment and contributing to sustainable development.Enhanced Durability and Performance of Hydraulic Systems

Reconditioned cylinders can perform like new, helping maintain system efficiency, minimize downtime, and reduce unexpected failures.

Hydraulic cylinder reconditioning is an effective solution for businesses to maintain and enhance hydraulic system performance. This process not only saves costs but also protects the environment and increases equipment durability. Modern technologies and techniques such as chromium plating, CNC machining, and TIG welding are continuously improving to achieve optimal reconditioning results. By adopting these methods, businesses can maintain stable hydraulic systems, ensuring long-term operation and economic benefits.

Thuy Luc Sai Gon: Experts in Hydraulic Cylinder Repair and Reconditioning

Thuy Luc Sai Gon is one of the leading companies in Vietnam specializing in hydraulic cylinder repair and reconditioning services for industrial hydraulic systems. With an experienced team of technicians and modern technologies, the company is committed to providing optimal solutions that save costs for customers while ensuring quality and outstanding performance.

Professional Hydraulic Cylinder Repair and Reconditioning Services

Thuy Luc Sai Gon offers hydraulic cylinder reconditioning and repair services for industrial equipment, including:

- Reconditioning heavy-duty hydraulic cylinders in machines and equipment that use high thrust, such as cranes, presses, excavators, etc.

- Repairing hydraulic piston rods, replacing worn parts like seals, O-rings, pistons, and cylinder tubes.

- Improving and maintaining hydraulic cylinder systems for long-lasting performance.

Detailed Hydraulic Cylinder Reconditioning Process

With the goal of optimizing operational efficiency and extending equipment lifespan, Thuy Luc Sai Gon follows a precise reconditioning process, ensuring maximum durability and reliability. The process includes:

- Surveying and Evaluating the Cylinder Condition

- Disassembling and Cleaning

- Machining and Reconditioning Parts

- Replacing Seals and O-Rings

- Reassembly and Performance Testing

Product and Service Quality

Thuy Luc Sai Gon guarantees reconditioned products that are 99% as good as new. The repaired products not only have high durability but can also operate effectively in harsh environments, such as temperatures ranging from 400-800 degrees Celsius or in corrosive environments like the sea and chemicals.

Furthermore, the company offers a 12-month warranty for all reconditioned products, ensuring customers can use them confidently during their operation.

Benefits of Choosing Thuy Luc Sai Gon for Hydraulic Cylinder Reconditioning

Cost Savings: Hydraulic cylinder repair and reconditioning at Thuy Luc Sai Gon costs only about 15% of the price of a new cylinder. This solution helps businesses save on investment costs while maintaining operational efficiency.

Extended Equipment Lifespan: Reconditioning and maintaining hydraulic systems extend equipment life, reducing the need for frequent replacements and improving work efficiency.

Expertise: With a highly skilled team, Thuy Luc Sai Gon ensures precise and professional reconditioning services, meeting the high technical demands of industrial hydraulic systems.

Quick Solutions: The repair process at Thuy Luc Sai Gon is quick and efficient, reducing operational downtime for customers.

- Electroless Plating!

Applications of Hydraulic Cylinders in Industry

Hydraulic cylinder systems are widely used in various industrial fields, including:

- Machine Manufacturing Industry: Hydraulic cylinders are used in machines such as presses, drills, and CNC machines.

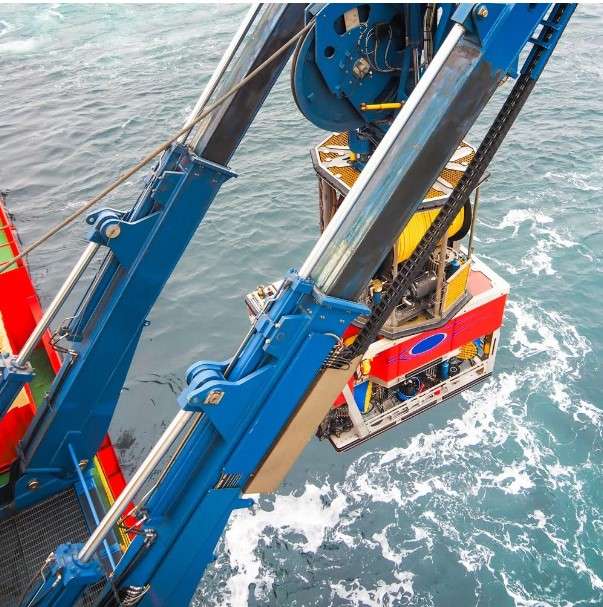

- Construction Industry: Used in equipment like cranes, excavators, and loaders.

- Transportation Industry: Hydraulic cylinders are used in lifting extremely large and heavy loads.

- Mineral Processing and Mining Industry: Equipment like crushers, screens, and hydraulic presses use hydraulic cylinders to increase thrust.

Commitment of Thuy Luc Sai Gon

Thuy Luc Sai Gon is committed to providing high-quality hydraulic cylinder reconditioning services, meeting the diverse needs of customers in various industries. We always prioritize quality and customer satisfaction, offering long-term warranties to ensure customers’ peace of mind regarding the performance and durability of our products.

Contact Thuy Luc Sai Gon

For more information on hydraulic cylinder reconditioning services, please contact us via the following channels:

Website: https://thuylucsaigon.com

Phone: 0903.863.762

Email: Thuylucsaigon@gmail.com

Address: 900 Quốc Lộ 1A, Bình Trị Đông A Ward, Bình Tân District, Ho Chi Minh City

Bình luận đã đóng.